Underfloor heating (UFH) has become a staple of modern comfort, particularly in homes and buildings across the UK. Multi-zone UFH systems—where each room or area of a home is heated independently—offer superior control, energy efficiency, and personalised comfort. However, as these systems become more complex, they’re also more susceptible to technical problems, one of the most common being flow rate imbalances. Whether you’re a homeowner in London or Edinburgh dealing with cold patches, uneven heating, or persistent pump issues, this article will guide you through common flow rate problems in multi-zone UFH systems and explain practical solutions that actually work.

Understanding Flow Rate in UFH Systems

In a wet UFH system (water-based), flow rate refers to the amount of heated water that passes through each loop or circuit of pipework beneath your floor. In multi-zone setups, these loops are divided into separate areas (zones), each controlled independently by thermostats and actuators. A correct and balanced flow rate is essential for maintaining even temperatures across zones, preventing heat loss or inefficiency, avoiding strain on the circulation pump, and maximising system lifespan.

What Causes Flow Rate Problems in Multi-Zone Systems?

Flow rate problems often stem from imbalances between zones. Some may receive too much hot water, while others get very little—or none at all. Let’s explore the common causes.

Improper Balancing of Manifolds

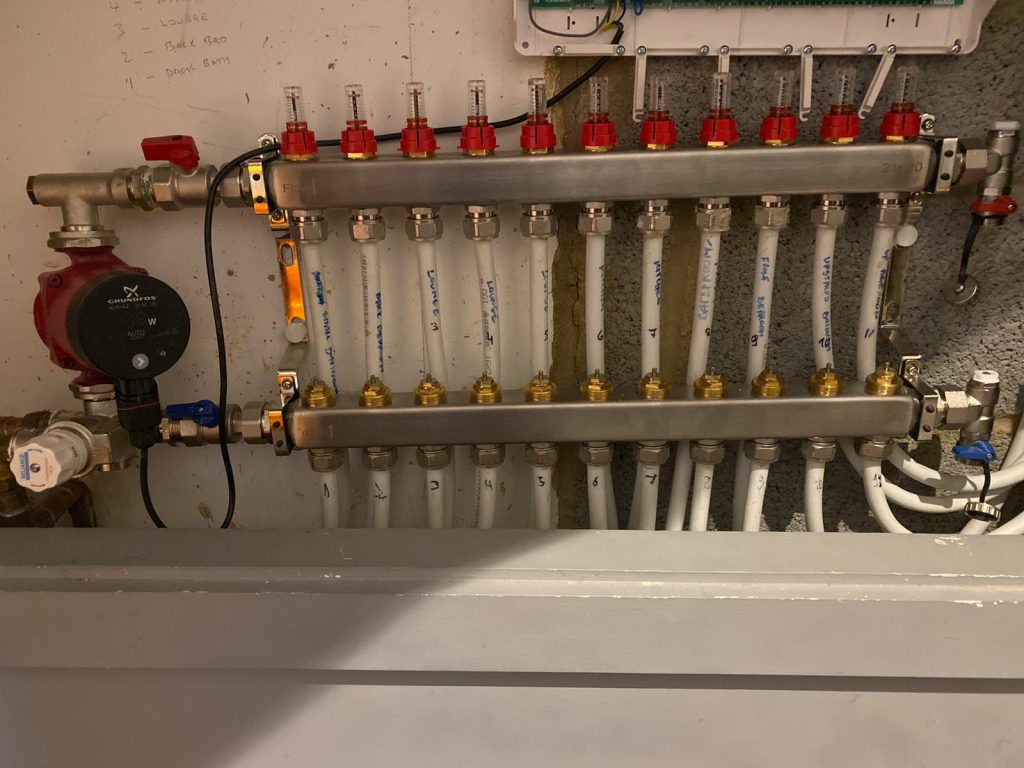

The manifold is the central hub of any wet UFH system. Each circuit has its own flow control valve, and balancing these manually ensures water flows evenly across zones. In many installations, especially DIY or budget jobs, this balancing is neglected or poorly done.

Airlocks in the Pipework

Air trapped in the system can block water flow, particularly in longer loops or those furthest from the pump. Multi-zone systems are more susceptible due to their complexity.

Blocked or Kinked Pipes

Over time, debris, sludge or limescale can reduce flow in specific loops. Similarly, if pipework was kinked during installation, water flow can be permanently restricted.

Faulty or Incorrect Pump Sizing

A circulation pump that’s too weak won’t deliver enough flow to all zones, while an oversized pump can cause noise, wear, and excessive flow in closer loops. Multi-zone systems often require a more powerful or variable-speed pump.

Thermostatic Actuator Failures

Actuators control whether each zone receives flow based on thermostat demand. If one or more actuators are stuck closed (or open), it can dramatically impact flow distribution.

Incorrect Flow Temperature

If the system’s mixing valve or boiler flow temperature is too low, flow rate might be adequate but still ineffective—because there isn’t enough thermal energy in the water to warm the space.

Signs You Have a Flow Rate Problem

One or more zones are significantly cooler than others. Some rooms overheat while others stay cold. Slow heat-up times or cold patches in the floor. Boiler short-cycling or running constantly. Pump making unusual noises or becoming hot. Thermostats calling for heat with no effect.

Diagnosing Flow Rate Issues in Multi-Zone UFH

Diagnosing the problem starts with a systematic approach. If you’re in London, where property sizes and zones may vary significantly, a tailored inspection is essential.

Check Thermostats and Actuators

Ensure each room thermostat is calling for heat. Visually inspect actuator pins—manually open them if needed to confirm movement.

Inspect the Manifold Flow Gauges

Most modern manifolds have transparent flow gauges showing real-time L/min readings. Identify zones with either zero flow or excessively high flow compared to others.

Bleed the System

Use the manifold bleed valves to remove trapped air from each loop. Bleed individual zones by closing off all others, then gradually opening them.

Pump Testing

Check pump settings (speed 1/2/3 or auto-adapt on newer models). Feel the temperature difference between the flow and return pipes.

Infrared Floor Scanning

A thermal imaging camera can help visualise uneven heat distribution across zones.

Practical Solutions That Work

Manual or Automatic Balancing of the Manifold

Use the flow meters on the manifold to manually adjust each loop’s flow rate. Match them to the calculated requirement (usually between 1.0 and 2.5 L/min depending on loop length and room size). If no flow meters are present, install them or consider upgrading the manifold. Shorter loops should have their flow restricted to allow longer ones sufficient volume.

Airlock Removal

Airlocks are one of the most common culprits in newly installed systems or after summer shutdowns. Open zone valves one by one and force water through each loop until it runs smoothly. In persistent cases, use a flushing pump to power-flush individual zones and check for air in high points and loop returns.

Upgrade Your Circulation Pump

A multi-zone UFH system requires a pump capable of maintaining sufficient pressure across all zones. If your system is struggling, consider a variable-speed pump with automatic pressure adjustment (e.g., Grundfos Alpha3 or Wilo Yonos) or a system with integrated balancing or feedback controls. Avoid mixing UFH and radiator loops on a single pump circuit without a separate mixer or diverter valve.

Install a Hydraulic Separator

In larger systems, especially when UFH is combined with radiators, a low-loss header or hydraulic separator balances flow between the boiler and UFH manifold. This avoids competition between circuits and ensures stable pressure and flow.

Clean and Flush the System

If sludge or scale is suspected, a power flush or chemical clean may be necessary. Magnetic filters (e.g., MagnaClean) should also be installed to protect against future blockages.

Check Flow Temperature Settings

Ensure your mixing valve or boiler controller is delivering around 35–55°C to the UFH manifold. Any lower, and the flow may be fine but the heating effect minimal.

Replace or Test Actuators

A stuck or failed actuator can block an entire loop. Test each one manually by removing the actuator head and checking the pin for movement. Replace any that are stuck or sluggish.

Preventing Future Flow Rate Problems

Once your system is back in working order, prevention is key. Schedule annual servicing with a qualified heating engineer to check flow, pressure, and performance. Use smart thermostats that allow scheduling and override across different rooms. Avoid DIY interference—don’t bleed UFH loops or adjust manifolds without understanding the impact. Bleed the system regularly, especially after long heating downtimes. Install digital sensors and monitors to alert you to early signs of imbalance or failure.

When to Call in a Professional

If your attempts at bleeding, balancing or pump adjustments haven’t resolved the issue, it’s time to call in a certified UFH engineer. London-based homes especially benefit from local professionals who understand the quirks of Georgian, Victorian, and mixed-use buildings. Signs you need help include repeated airlocks despite bleeding, one zone staying cold no matter what, boiler or pump constantly cycling, UFH never working properly since installation, or uncertainty about the original system design.

Final Thoughts

Flow rate problems in multi-zone underfloor heating systems can be frustrating and difficult to diagnose without a solid understanding of hydraulics and system dynamics. Fortunately, with the right approach, tools, and knowledge, many of these issues can be solved without replacing your entire system. Whether you’re a homeowner tackling patchy heating or a landlord dealing with tenant complaints, getting the flow rate right in your UFH system is essential to ensuring comfort, efficiency, and long-term performance. If you need help restoring balance to your UFH system in London or surrounding areas, speak to a local underfloor heating repair expert to get your system running at its best.